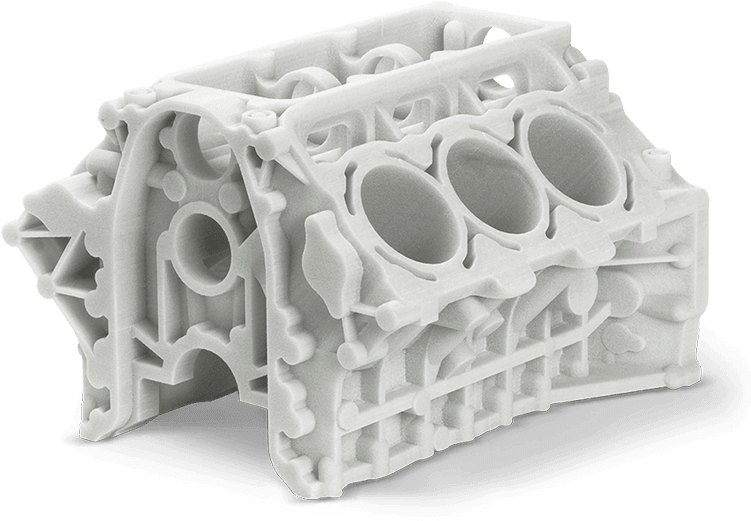

PA2200 - Nylon 12

PA2200 is a type of polyamide (nylon) powder used in Selective Laser Sintering (SLS) 3D printing. It is a popular material choice for SLS due to its properties, which include:

High Strength and Durability: PA2200 offers excellent mechanical properties, including high tensile strength and impact resistance, making it suitable for functional prototypes and end-use parts.

Heat Resistance: It has a relatively high melting point, allowing printed parts to withstand elevated temperatures without deforming.

Chemical Resistance: PA2200 is resistant to many chemicals, oils, and greases, making it suitable for applications where exposure to these substances is expected.

Versatility: It can be used to print a wide range of complex geometries without the need for support structures, thanks to its ability to self-support during printing.

Surface Finish: Parts printed with PA2200 typically have a smooth surface finish, requiring minimal post-processing.

Due to these properties, PA2200 is commonly used in industries such as aerospace, automotive, healthcare, and consumer goods for producing functional prototypes, end-use parts, and custom components.

Build Volume

200 x 200 x 330 mm

7.8 x 7.8 x 13 in

Layer Heights

100 Micron

200 Micron