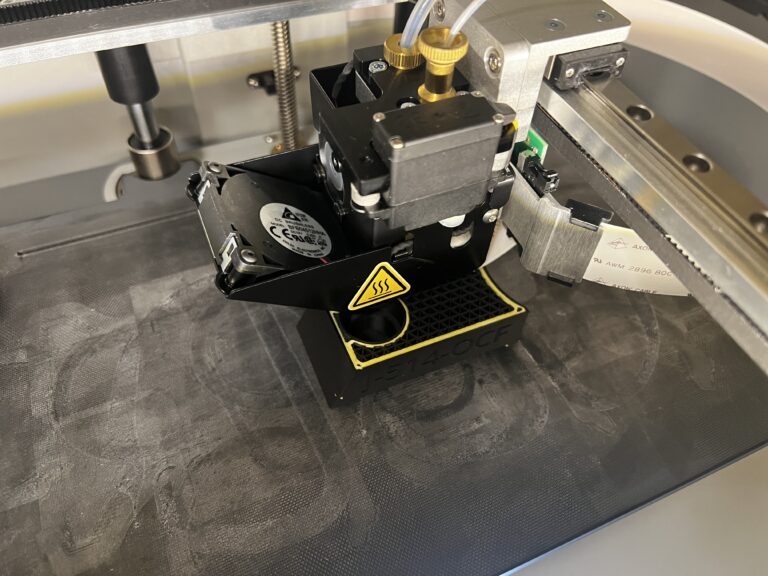

Markforged onyx®

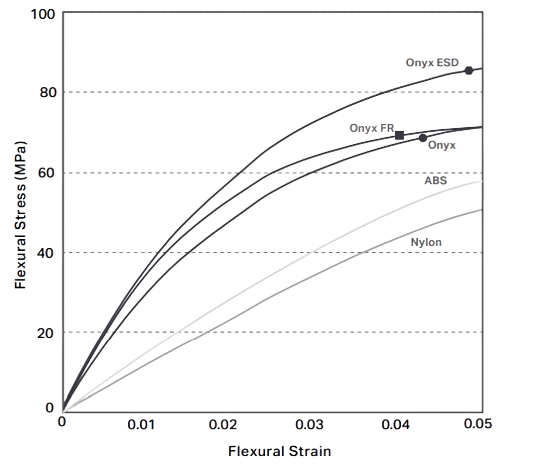

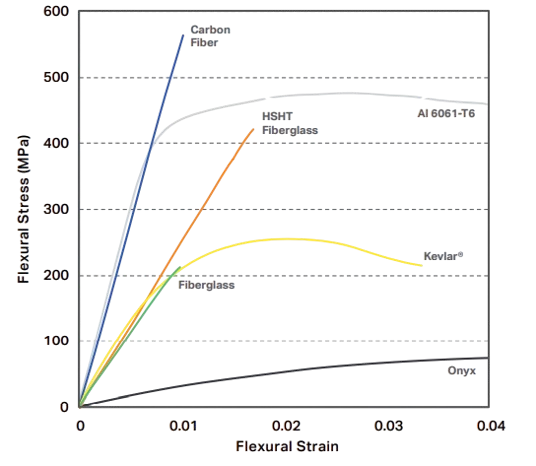

Onyx, a thermoplastic made from nylon infused with chopped carbon fiber, can be used independently or combined with continuous fibers for reinforcement. This enhances its strength to a level similar to aluminum. Suitable for various applications, Onyx is ideal for creating tools, fixtures, and even final production components.

Build Volume

320 x 132 x 150 mm

12.2 x 5.2 x 5.9 in

Infills Offered

40-100%

Layer Heights

100 Micron

200 Micron