What is SLS (Selective Laser Sintering) 3D Printing? SLS Printed...

In the dynamic world of 3D printing, Fused Deposition Modeling (FDM) stands out as a popular and accessible technology, especially for those new to the realm of additive manufacturing. At its core, FDM 3D printing involves the precise layering of heated materials to create three-dimensional objects. This technology has revolutionized prototyping and manufacturing, offering unparalleled flexibility in design and material choice.

As a beginner (or even as an advanced user!), understanding the vast array of materials available for FDM 3D printing can be overwhelming. Each material brings its unique set of properties and capabilities, making the choice crucial for the success of your project. Whether you’re an enthusiast embarking on a personal project or a professional exploring cost-effective prototyping solutions, this guide aims to demystify the selection process.

In this comprehensive guide, we’ll explore the different types of FDM 3D printing materials, delve into the factors you should consider when choosing a material, highlight the common applications of various materials, and provide practical tips for first-time users. By the end of this article, you’ll have a solid understanding of how to navigate the world of FDM 3D printing materials, ensuring your next project not only takes shape but excels in its intended purpose.

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a key technology in the world of 3D printing. This method is cherished for its simplicity and cost-effectiveness, becoming a pivotal approach in rapid prototyping and personal manufacturing. For newcomers to 3D printing, FDM serves as an accessible entry point for creating complex and functional designs.

FDM operates by extruding thermoplastic filaments through a heated nozzle, melting the material. This melted filament is then precisely laid down in layers on the build platform. Each layer cools and solidifies quickly, and the build platform lowers to accommodate the addition of the next layer. This process repeats until the entire object is completed.

FDM is celebrated for its straightforward approach and ability to create durable parts with reasonable accuracy. It’s particularly favored for producing prototypes or parts quickly, making it an ideal choice for hobbyists, educators, and professionals.

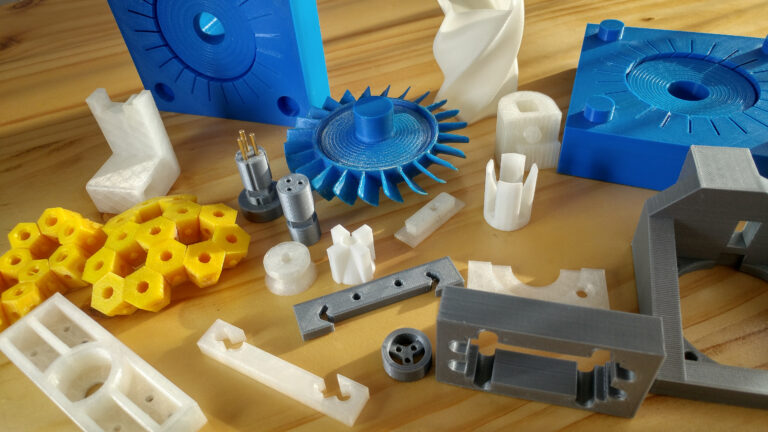

A significant advantage of FDM 3D printing is the diverse range of materials available, each offering unique properties like heat resistance, strength, and flexibility. The most commonly used materials include:

FDM 3D printing exemplifies the democratization of manufacturing. Its ease of use, affordability, and diverse material options make it an excellent platform for creativity and practical application. Whether you’re a hobbyist bringing your ideas to life or a professional prototyping a new product, FDM 3D printing offers the flexibility and tools needed to embark on your 3D printing journey.

When diving into FDM 3D printing, one quickly realizes the significance of choosing the right material. Each material not only behaves differently during the printing process but also impacts the final properties of the printed object. Let’s explore some of the most common FDM 3D printing materials, highlighting their characteristics and typical uses.

Each material requires different printing settings, such as temperature and speed, to achieve the best results. For instance, PLA can be printed on a cold bed, whereas ABS might require a heated bed and enclosed printer for optimal results. TPU, with its flexibility, often needs slower printing speeds to prevent issues during extrusion.

Selecting the right material for Fused Deposition Modeling (FDM) 3D printing is crucial to the success of your project. The choice of material can affect the durability, appearance, and functionality of the printed object. Here are some key factors to consider when choosing a material for FDM 3D printing:

Balancing these factors depends on your specific project needs. For example, if you’re creating a functional part for a machine, strength and temperature resistance might be your top priorities. On the other hand, if you’re printing a decorative model, you might prioritize surface finish and ease of printing.

Understanding these factors and how they relate to your project’s requirements will help you make an informed decision, ensuring that your FDM 3D printing endeavor is successful and satisfying.

The choice of material in Fused Deposition Modeling (FDM) 3D printing is not just about the physical properties; it also defines the potential applications of the printed object. Each material offers unique capabilities, making it suitable for specific uses. Let’s explore the common applications of various FDM 3D printing materials:

Each material brings its strengths to different applications, and understanding these can significantly influence the success of your printing project. For instance, while PLA is great for an initial prototype, ABS or PETG might be better choices for the final functional part due to their higher durability and resistance to temperatures.

Experimenting with different materials is a key part of the 3D printing journey. While PLA might be the starting point for most beginners due to its ease of use, venturing into materials like ABS and PETG can open new doors for more demanding applications. Similarly, experimenting with TPU can add a new dimension to your projects, enabling you to create flexible and resilient parts.

The choice of material should always be aligned with the purpose of your 3D printed object. For decorative items or models that don’t require much strength or heat resistance, PLA is an excellent choice. In contrast, for parts that will undergo stress, exposure to heat, or outdoor conditions, materials like ABS and PETG are more appropriate. TPU, with its unique flexibility, is unrivaled for items that need to bend or cushion impacts.

Understanding the common applications of different FDM 3D printing materials is crucial in making an informed decision that ensures the functionality and longevity of your 3D printed projects.

Welcome to the exciting world of FDM 3D printing! As you embark on your journey with our service, choosing the right material for your project is paramount. Here are some tailored tips to help you navigate our material options and ensure the success of your print:

By following these guidelines, you can confidently select the right material for your 3D printing project on our platform. Our goal is to make your 3D printing experience seamless and successful, ensuring that the end product perfectly aligns with your vision.

As we’ve explored in this guide, the choice of material in FDM 3D printing is a critical decision that shapes the outcome of your projects. Whether you are a beginner embarking on your first 3D printing adventure or a seasoned professional, understanding the properties and applications of different materials is key to achieving your desired results.

On our 3D printing service platform, we strive to make this selection process as straightforward and informative as possible. By offering a diverse range of materials, detailed guides, and expert assistance, we aim to empower you to make choices that align perfectly with your project needs.

Remember, each material brings its unique set of characteristics and possibilities. PLA offers ease and safety for beginners, ABS provides durability for functional parts, PETG balances ease of use with strength, and TPU introduces flexibility into your creations. Embracing the diversity of these materials opens up a world of creativity and innovation.

We encourage you to experiment, learn, and grow with each project. The world of FDM 3D printing is constantly evolving, and staying curious and informed will help you make the most of this exciting technology. Our team is always here to support you, ensuring that every project you undertake with us is not just a success but also a step forward in your 3D printing journey.

Thank you for choosing our service for your 3D printing needs. We look forward to seeing your ideas come to life and helping you push the boundaries of what’s possible with FDM 3D printing.

What is SLS (Selective Laser Sintering) 3D Printing? SLS Printed...

SLA (Stereolithography) 3D printing is an advanced additive manufacturing technology...

FDM 3D printing, also known as Fused Deposition Modeling, is...

Adding threads to 3D printed parts is essential for creating...

Copyright © 2023 Print my Parts

Copyright © 2023 Print my Parts